How Is Terrazzo Made? Sustainable Floors & Countertops

Inorganic terrazzo is becoming increasingly popular in residential and commercial design due to its durability, visual appeal, and eco-friendliness. Unlike traditional cement-based terrazzo, it is more moisture-resistant and easier to maintain. Whether you are interested in terrazzo floors, countertops, or other terrazzo surfaces, understanding how inorganic terrazzo is made is crucial for making the right choice for your project.

What Is Inorganic Terrazzo?

Before diving into the manufacturing process, it's important to answer the fundamental question: What is terrazzo? Inorganic terrazzo, also known as engineered terrazzo, is a composite material made from aggregates such as marble chips, glass, granite, or quartz, combined with a binder that does not contain resin.

The aggregates used in inorganic terrazzo are typically sourced from natural stone or recycled materials, making it an eco-friendly option. The binder used in inorganic terrazzo is more water-resistant and stain-resistant compared to traditional cement, which helps improve the material’s longevity and performance.

Unlike traditional terrazzo, which uses cement as the binding agent, inorganic terrazzo is particularly well-suited for environments that require extra moisture resistance, such as kitchens, bathrooms, and outdoor applications.

The Process of Making Inorganic Terrazzo Floors

The process of creating an inorganic terrazzo floor involves several steps to ensure the final product is durable, attractive, and eco-friendly. Let’s take a closer look at how this material is made:

1. Preparation of the Subfloor

Before pouring the terrazzo mixture, it’s essential to prepare the subfloor or base. Inorganic terrazzo can be installed over a variety of surfaces, including concrete, existing tiles, or even wooden floors, as long as the surface is clean, dry, and level. A bonding layer or primer is often applied to ensure that the terrazzo mixture adheres properly to the subfloor.

2. Selection of Aggregates

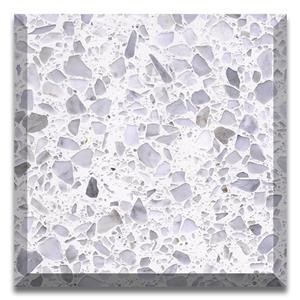

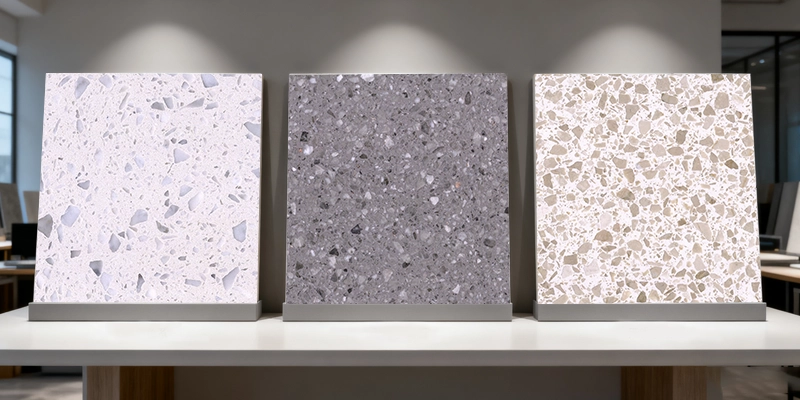

The key to creating a unique terrazzo floor lies in the selection of aggregates. For inorganic terrazzo, these aggregates can be made from various natural stones such as marble chips, granite, quartz, and even recycled glass or industrial byproducts. The size and color of the aggregates can be adjusted based on the aesthetic preferences of the client, from small, fine chips to larger, bolder pieces that create a more striking effect.

Choosing the right aggregates is crucial not only for visual appeal but also for the durability of the finished floor. Inorganic terrazzo can incorporate materials like recycled glass, offering an eco-friendly option for projects focused on Eco-friendly.

3. Mixing the White Cement and Aggregates

Once the aggregates are selected, they are mixed with white cement. This step is crucial for the product's performance, as it binds the aggregates together and ensures the surface is moisture-resistant, stain-resistant, and scratch-resistant. The mixture is carefully blended to ensure the ratio of cement to aggregates is optimal for achieving the best durability and appearance.

At this stage, pigments can also be used to color the mixture, further adjusting the look of the terrazzo floor. The flexibility in color and design is one of the reasons why terrazzo is such a popular choice for modern design projects.

4. Pouring the Terrazzo Mixture

After the white cement and aggregates are thoroughly mixed, the next step is to pour the mixture onto the prepared surface. The terrazzo mixture is spread evenly across the surface using specialized tools. This stage requires skill and precision to ensure that the thickness of the terrazzo layer is uniform and that the aggregates are evenly distributed.

For larger projects, terrazzo can be poured in sections, with each section poured and smoothed individually to ensure a seamless finish. Once the terrazzo is poured, it is left to cure for a set period.

5. Grinding and Polishing

Once the terrazzo mixture has cured and hardened, the floor needs to be ground to smooth out any rough spots or imperfections. This step is essential for revealing the full beauty of the aggregates. A specialized terrazzo grinder is used to remove the top layer of the surface, exposing the embedded chips of marble, glass, or other materials.

Once grinding is complete, the floor is polished to create a high-gloss finish. The terrazzo floor polishing process may take several hours, depending on the desired level of shine. The final result is a smooth, durable, and visually appealing surface that showcases the unique patterns and colors of the terrazzo aggregates.

How Terrazzo Countertops Are Made

The production process for inorganic terrazzo countertops is very similar to that of terrazzo floors but with some key differences. Instead of pouring the mixture directly onto the floor, the terrazzo mixture is poured into molds to create custom shapes for countertops. This allows for greater design flexibility and adjustment.

Like terrazzo floors, terrazzo countertops can be made from various aggregates, from recycled glass to natural stones like marble and granite. Once the mixture is poured and cured, the countertops are ground and polished to reveal the intricate patterns formed by the aggregates. The final product is a smooth, flat, and durable countertop that can withstand the rigors of daily use while showcasing a unique aesthetic.

Why Choose Inorganic Terrazzo?

Inorganic terrazzo is the ideal choice for both residential and commercial projects for several reasons:

Durability: Inorganic terrazzo is incredibly strong and resistant to scratches, moisture, and stains. This makes

it the perfect material for high-traffic areas like floors and countertops.

Eco-Friendliness: Many inorganic terrazzo products incorporate recyclable materials such as glass, helping

to reduce environmental impact. By choosing terrazzo, you’re contributing to eco-friendly building practices.

Flexibility: The wide range of available aggregates and the ability to add custom pigments means that terrazzo

can be adjusted to suit virtually any design vision, from classic to modern.

Low Maintenance: Inorganic terrazzo is easier to clean and maintain than traditional cement-based terrazzo.

It requires periodic sealing to protect the surface, but its overall maintenance needs are minimal.

Terrazzo and Marble Suppliers: How to Find the Best Materials

When sourcing terrazzo and marble supply for your project, it's essential to choose a reliable supplier that offers high-quality materials. Look for a supplier that provides a variety of aggregates, white cement, and customization options. They should also be able to offer guidance on design choices, installation techniques, and maintenance tips.

Choosing the right materials for your inorganic terrazzo project ensures that the final result will not only meet your aesthetic goals but will also perform well over time. High-quality aggregates and binders can make a significant difference in the durability and appearance of your terrazzo surfaces.

In conclusion, inorganic terrazzo offers a versatile, durable, and eco-friendly option for a wide range of applications, from floors to countertops. Its moisture and stain resistance, combined with flexible design options, make it a popular choice in modern interior design. By understanding the process of how inorganic terrazzo is made, you can make an informed decision for your next design project. Whether you're creating terrazzo floors, countertops, or other surfaces, inorganic terrazzo provides a beautiful, long-lasting, and environmentally friendly solution.