Precast Inorganic Terrazzo vs. Poured Terrazzo: Which Is More Durable?

Precast Inorganic Terrazzo vs. Poured Terrazzo:

Which Is More Durable?

When it comes to choosing the right terrazzo flooring for commercial or residential spaces, durability is often one of the top

concerns. Two major types dominate the market: precast inorganic terrazzo and poured-in-place terrazzo. While both offer

distinct aesthetic and performance qualities, how do they compare in terms of long-term durability?

This article explores the strengths and weaknesses of each, helping you decide which is better suited for your project.

What Is Precast Inorganic Terrazzo?

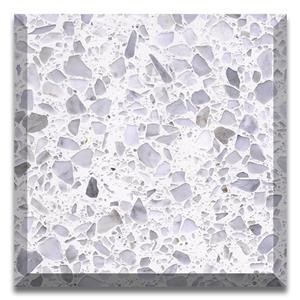

Precast terrazzo, especially the inorganic type, is manufactured in a controlled factory setting. It’s made from

cement-based (non-resin) binders mixed with stone, glass, or metal chips. The mixture is poured into molds, vibrated to remove

air bubbles, compressed for density, and cured before being polished and transported to the site.

What Is Poured-in-Place Terrazzo?

Poured terrazzo (also known as site-poured terrazzo) is mixed and installed directly on the construction site. Workers spread

the cement or epoxy mix over the substrate, embed the aggregates, and then grind and polish the floor on-site after it cures.

While this traditional method offers seamless flooring, it relies heavily on on-site skill and conditions.

Durability Comparison: Key Factors

1. Density and Structural Strength

Precast terrazzo achieves higher compressive strength (60–80 MPa) due to factory-controlled vibration and molding.

Poured terrazzo usually ranges from 30–50 MPa, with greater variability due to field conditions.

✅ Winner: Precast terrazzo — stronger and more consistent.

2. Crack Resistance and Water Absorption

Precast terrazzo has minimal shrinkage and lower porosity, making it highly resistant to cracking and moisture intrusion.

Poured terrazzo is prone to shrinkage cracks, especially when installed without proper expansion joints or in varying humidity.

✅ Winner: Precast terrazzo — more dimensionally stable.

3. Wear Resistance and Surface Longevity

Precast terrazzo flooring is polished under controlled conditions, achieving a denser, glossier, and more durable surface

that resists abrasion even in high-traffic zones.

Poured terrazzo is also wear-resistant but more prone to uneven polish or premature wear due to inconsistent site finishing.

✅ Winner: Precast terrazzo — longer-lasting surface finish.

4. Ease of Maintenance and Repair

Precast terrazzo panels allow for modular installation and easier replacement of damaged tiles.

Poured terrazzo, once damaged, usually requires full-area refinishing or costly repairs.

✅ Winner: Precast terrazzo — better for long-term maintenance planning.

5. Expected Lifespan

Precast inorganic terrazzo can last 20 to 30 years or more with minimal maintenance, especially in commercial applications

such as airports, malls, and hospitals.

Poured terrazzo typically lasts 10 to 15 years, though quality installations may last longer under ideal conditions.

✅ Winner: Precast terrazzo — longer service life and return on investment.

Durability Summary Table

Feature | Precast Inorganic Terrazzo | Poured Terrazzo |

Compressive Strength | ★★★★★ (60–80 MPa) | ★★★ (30–50 MPa) |

Crack & Moisture Resistance | ★★★★☆ | ★★ |

Wear Resistance | ★★★★★ | ★★★ |

Maintenance Flexibility | ★★★★★ | ★★ |

Lifespan | 20–30 years | 10–15 years |

Overall Durability | ✅ Excellent | ⚠️ Moderate |

Final Verdict: Which Terrazzo Type Is More Durable?

In most commercial and high-demand environments, precast inorganic terrazzo clearly outperforms its poured-in-place

counterpart in terms of strength, lifespan, and long-term stability. Though initial costs may be slightly higher, the reduced

maintenance and replacement expenses make it a smarter investment over time.

If you're planning a high-traffic public space or want a flooring solution with minimal upkeep, precast terrazzo panels are the

clear winner.