Precast Terrazzo vs Traditional Terrazzo: Key Differences

As terrazzo flooring continues to gain popularity in commercial and architectural projects, understanding the difference between precast terrazzo and traditional terrazzo is essential. While both originate from the same material concept, their production methods, performance characteristics, and design flexibility differ significantly. Choosing the right terrazzo system directly impacts durability, aesthetics, installation efficiency, and long-term maintenance.

This article explores the key differences between precast terrazzo and traditional terrazzo, helping designers and project owners make informed decisions.

What Is Terrazzo and How It Is Traditionally Made

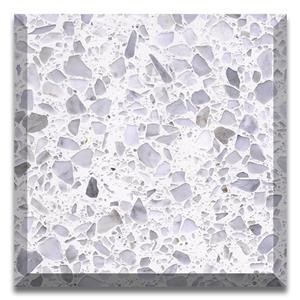

To understand the difference, it is important to first clarify what is terrazzo. Terrazzo is a composite material made of marble aggregates combined with a cementitious or resin-based binder, then ground and polished to achieve a smooth, durable surface.

Traditional terrazzo is typically poured in place on-site. The terrazzo mixture is applied directly to the substrate, cured, and then polished in multiple stages. This method has been used for decades, especially in institutional buildings such as schools, hospitals, and public facilities.

While traditional terrazzo offers seamless surfaces and classic appeal, it also presents challenges in quality control, construction timelines, and on-site coordination.

What Is Precast Terrazzo

Precast terrazzo refers to terrazzo products that are manufactured in a controlled factory environment before being transported to the project site. These products include terrazzo slabs, tiles, stair treads, wall panels, and custom architectural elements.

Each terrazzo slab is produced under strict conditions, allowing precise control over aggregate distribution, color consistency, curing, and surface finish. Once fabricated, precast elements are installed similarly to natural stone or ceramic tiles, significantly reducing on-site wet work.

Key Differences Between Precast Terrazzo and Traditional Terrazzo

Manufacturing Process and Quality Control

Traditional terrazzo relies heavily on on-site workmanship, environmental conditions, and curing time. Variations in temperature, humidity, and labor skill can affect the final result.

Precast terrazzo, by contrast, is produced using standardized molds and calibrated processes. Factory production ensures consistent thickness, uniform texture, and stable structural performance across all terrazzo slabs.

Installation Efficiency and Project Timeline

Traditional terrazzo flooring requires multiple on-site steps, including pouring, curing, grinding, polishing, and sealing. This can extend project timelines and increase coordination complexity with other trades.

Precast terrazzo significantly shortens installation time. Finished terrazzo slabs are delivered ready for installation, reducing labor intensity and allowing faster project turnover—an important advantage for large-scale commercial developments.

Structural Stability and Durability

Because precast terrazzo is cured under controlled conditions, it typically exhibits higher dimensional stability and reduced risk of cracking or shrinkage. This makes it especially suitable for high-traffic environments.

Traditional terrazzo can achieve excellent durability, but its long-term performance depends heavily on substrate preparation and on-site execution quality.

Design Flexibility and Customization

Both systems support creative terrazzo design, but in different ways.

Traditional terrazzo allows for seamless, joint-free surfaces and intricate inlay patterns directly on-site. However, design changes during installation can be costly and time-consuming.

Precast terrazzo offers extensive customization before production. Aggregate size, color blends, edge profiles, surface finishes, and panel dimensions can be precisely defined in advance. This makes precast terrazzo ideal for projects requiring repetitive elements or complex architectural detailing.

Maintenance and Lifecycle Performance

Both precast terrazzo and traditional terrazzo flooring are known for their long service life and low maintenance requirements. However, precast terrazzo slabs benefit from factory-controlled polishing and sealing, often resulting in more consistent surface performance over time.

In high-use commercial environments, precast terrazzo provides predictable maintenance cycles and easier replacement of individual panels if required.

Choosing the Right Terrazzo System for Your Project

The choice between precast terrazzo and traditional terrazzo depends on several factors:

Project scale and schedule

Design complexity and repetition

On-site construction conditions

Long-term performance requirements

For large commercial projects, prefabricated construction methods increasingly favor precast terrazzo slabs due to efficiency, consistency, and reduced risk. Traditional terrazzo remains suitable for projects prioritizing seamless surfaces and on-site craftsmanship.

Conclusion

Both precast terrazzo and traditional terrazzo share the same material heritage, yet their differences in production, installation, and performance make them suitable for distinct applications. As terrazzo flooring continues to evolve, precast terrazzo has become a preferred solution for modern architectural projects that demand precision, durability, and design flexibility.

Understanding these key differences allows architects, developers, and contractors to select the terrazzo system that best aligns with their design intent and project requirements.