Is Terrazzo Floor a Future-Proof Choice for Large Buildings?

Material selection in large-scale construction is no longer based solely on appearance or initial cost. Architects, developers, and contractors increasingly evaluate materials through the lens of long-term performance, lifecycle value, and adaptability to changing design standards. Within this context, terrazzo has regained attention. Once associated primarily with historic institutional buildings, terrazzo is now being reconsidered for modern commercial and public developments.

This raises an important question: is terrazzo a future-proof material for large buildings? To answer this, it is necessary to examine how terrazzo floors perform over time, how terrazzo slabs are manufactured, and how evolving terrazzo design capabilities align with contemporary construction demands.

Durability and Long-Term Structural Stability

A future-proof material must demonstrate durability under sustained use. Large buildings—such as airports, hospitals, universities, and corporate campuses—place exceptional demands on floor systems. Heavy foot traffic, cleaning cycles, equipment movement, and environmental fluctuations all test surface integrity.

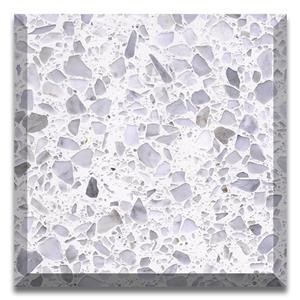

A properly installed terrazzo floor is known for its dense composition and abrasion resistance. Because terrazzo combines stone aggregates with a cementitious or inorganic binder, it forms a solid surface that resists wear more effectively than many alternative floor systems. Unlike vinyl or laminate products, terrazzo does not rely on surface coatings that degrade over time. Instead, its strength is inherent to the material structure.

In large buildings where flooring replacement can disrupt operations and increase costs, this long service life is a critical advantage. Many terrazzo floors installed decades ago remain functional today, illustrating the material’s capacity for sustained performance.

Precast Terrazzo and Construction Efficiency

Another factor influencing whether a material is future-proof is its compatibility with modern construction methods. Fast-track construction schedules and modular building systems require materials that can integrate efficiently into controlled workflows.

The rise of precast terrazzo has significantly improved installation efficiency. Instead of relying exclusively on poured-in-place systems, contractors can now specify factory-produced terrazzo slabs or tiles. Precast terrazzo offers consistent thickness, controlled curing conditions, and reduced on-site labor variability. For large buildings with tight timelines, this predictability minimizes risk.

A terrazzo slab manufactured in a controlled environment ensures dimensional accuracy and uniform surface quality. This consistency supports better coordination between trades and reduces installation delays—an increasingly important consideration in large commercial projects.

Design Flexibility in Evolving Architectural Environments

Future-proof materials must also remain relevant as design trends shift. Modern architectural spaces demand flexibility in color, texture, and pattern. Terrazzo design has evolved far beyond its traditional speckled appearance. Today, designers can specify aggregate size, color combinations, and visual density with precision.

Large public buildings often require cohesive visual strategies that extend across multiple floors and zones. Terrazzo flooring allows for seamless integration of wayfinding elements, subtle zoning distinctions, or branding features without disrupting spatial continuity. Because terrazzo design can be customized at scale, it adapts to both minimalist contemporary interiors and more expressive commercial spaces.

This adaptability positions terrazzo as a material capable of evolving alongside architectural trends rather than becoming visually outdated.

Lifecycle Value and Maintenance Considerations

Long-term maintenance requirements are central to future-proof evaluation. Building owners increasingly assess flooring systems based on lifecycle cost rather than initial installation price alone.

A terrazzo floor typically requires routine cleaning and periodic polishing but does not demand frequent replacement. Its non-porous surface resists staining when properly sealed, and its structural density limits surface damage from regular use. In large facilities where maintenance budgets are carefully monitored, this predictable upkeep contributes to stable operational planning.

When compared with floor systems that require periodic removal and replacement, terrazzo can offer lower long-term expenditure despite higher upfront investment. For developers focused on long-term asset performance, this durability supports financial sustainability.

Integration Within Modern Supply Networks

Material availability and supply reliability also influence long-term viability. The expansion of terrazzo and marble supply networks has improved access to standardized terrazzo slabs and precast systems worldwide. As suppliers refine production methods and distribution logistics, large-scale projects benefit from more consistent material sourcing.

In regions where natural stone supply can fluctuate due to quarry limitations or transportation challenges, terrazzo offers greater manufacturing control. Because aggregates can be sourced from multiple materials —including recycled content—terrazzo production is less dependent on a single geological origin. This flexibility strengthens its resilience within global construction supply chains.

Performance Compared to Alternative Materials

To determine whether terrazzo is truly future-proof, it is helpful to compare it with alternative flooring systems commonly used in large buildings. Polished concrete offers cost advantages but may present cracking risks over time. Large-format porcelain tiles provide visual uniformity but introduce joint lines that can interrupt expansive spaces. Natural stone conveys prestige but often introduces variability and higher maintenance demands.

Terrazzo occupies a balanced position among these options. It provides visual consistency comparable to engineered materials while retaining the depth and texture of stone aggregates. Its durability exceeds many synthetic surfaces, and its design adaptability allows it to compete with more contemporary finishes.

Environmental and Operational Considerations

Large buildings increasingly prioritize long-term operational performance and responsible material choices. Terrazzo can incorporate recycled aggregates such as glass or reclaimed stone fragments, reducing material waste. Additionally, the extended lifespan of terrazzo flooring reduces the environmental impact associated with repeated replacement cycles.

While environmental considerations vary by project and region, the ability to integrate recycled content and extend material lifespan contributes to terrazzo’s relevance in forward-looking construction strategies.

Conclusion

So, is terrazzo a future-proof material for large buildings? When evaluated through the lenses of durability, construction efficiency, design flexibility, lifecycle value, and supply reliability, terrazzo demonstrates many characteristics associated with long-term viability.

A well-designed terrazzo floor—whether installed as a poured system or specified as a precast terrazzo

slab—offers resilience in high-traffic environments, adaptability in evolving architectural contexts, and predictable performance across decades of use. As large buildings continue to demand materials that balance aesthetics with operational stability, terrazzo remains not only historically proven but strategically aligned with modern construction priorities.