Why Precast Terrazzo Is Ideal for Large Projects: Terrazzo Floor Guide

Why Precast Terrazzo Is Ideal for Large Projects: Terrazzo Floor Guide

When architects and contractors plan large-scale projects, they look for materials that combine long-term performance, visual consistency, and predictable installation timelines. Precast terrazzo has become one of the strongest contenders for this purpose. Its durability, elegant appearance, and controlled production process make it an excellent choice for airports, schools, hotels, retail centers, and government facilities.

To understand why this material performs so well, it's important to begin with the basics of what is terrazzo and how precast systems differ from traditional methods.

Understanding the Foundations of Terrazzo

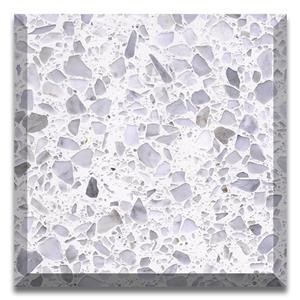

Before discussing precast applications, designers often start by asking what is terrazzo flooring and why it remains relevant in modern construction. Terrazzo is a composite material created by mixing natural aggregates—such as marble, quartz, or granite—into a cement or mineral-based binder. After curing, the surface is ground and polished to reveal a smooth, stone-like finish with exceptional durability.

Factories manufacture precast terrazzo using the same formula but under controlled conditions, producing slabs, steps, panels, countertops, and other elements with consistent color, density, and finish. This approach eliminates many of the environmental variables present on construction sites.

Why Precast Terrazzo Excels in Large Projects

1. Faster and More Predictable Installation

For large commercial developments, project schedules are often tight. Precast terrazzo products—such as panels and stair components—arrive ready to install, reducing labor hours and minimizing on-site work. Precast components install quickly and efficiently because they do not require on-site curing or extensive polishing like traditional poured terrazzo..

This efficiency is especially beneficial in commercial flooring projects, where multiple contractors work simultaneously and flooring delays can affect the entire construction timeline.

2. Consistent Quality Across Big Spaces

One of the biggest challenges in massive buildings is maintaining visual consistency. Producers create precast terrazzo slabs and panels with strict color controls to ensure consistent aggregates and a uniform finish. This helps maintain a cohesive look across thousands of square meters, whether the design calls for a smooth terrazzo floor or large wall panels.

3. Better Structural Stability and Stronger Performance

Factory-controlled casting reduces shrinkage, cracks, and curing problems. Precast terrazzo elements are also denser than many poured-in-place floors, offering improved longevity. These advantages help the material withstand high foot traffic, rolling loads, and environmental changes—making it reliable for airports, transportation hubs, and other heavy-use facilities.

4. Design Flexibility Through Precast Shapes

Precast manufacturing allows architects to specify customized shapes and sizes, including curved elements, stair treads, countertops, reception desks, and façade panels. These components complement terrazzo tile installations and offer unlimited design expressions without compromising performance.

5. Lower Long-Term Maintenance Requirements

Terrazzo is well known for its low maintenance needs. Routine cleaning is simple, and occasional professional polishing restores its gloss. Because of its dense and non-porous surface, it resists stains and moisture, making it suitable for education, healthcare, and service spaces projects. Low upkeep is also one of the main reasons building owners consider the overall terrazzo flooring cost to be highly economical over the lifespan of the material.

Supporting Sustainable and Modern Design Approaches

As more architects focus on interior design with sustainable materials, precast terrazzo aligns well with green building strategies. Its mineral-based composition contains no resin, and many manufacturers use recycled aggregates or stone offcuts. Terrazzo's very long lifespan reduces the need for replacement, significantly lowering material waste across decades of use.

Moreover, the production of precast components often results in less on-site dust, reduced noise, and more controlled resource usage—important considerations for environmentally sensitive construction.

Choosing Reliable Material Partners

Large projects rely on consistent, high-quality materials supplied on time. Working with experienced companies specializing in terrazzo and marble supply ensures steady access to well-produced aggregates, binders, and finished precast elements. These suppliers also help with color matching, technical guidance, and performance testing, which are crucial when specifying terrazzo for major commercial developments.

argeted supplier support plays a critical role when international shipping, site coordination, and long production runs are part of the project.

Why Precast Terrazzo Is a Smart Future-Proof Material

While trends in architecture and building design evolve, the core strengths of terrazzo remain constant: durability, timeless appearance, and exceptional value. Precast terrazzo enhances these qualities by adding stable results, speed, and manufacturing precision.

Whether the goal is visual elegance for a lobby, long-term durability for a school, or customized components for a contemporary public building, precast terrazzo offers a solution that adapts to diverse needs while maintaining lasting beauty.

For developers and designers searching for a proven material that performs reliably at scale, precast terrazzo continues to stand out as a smart and forward-thinking choice.