Precast Terrazzo vs Poured Terrazzo

Precast Terrazzo vs Poured Terrazzo

Terrazzo has been used as an design surface for centuries, yet it continues to evolve with modern construction methods. Today, architects and developers often face a key decision when specifying terrazzo for a project: choosing between precast terrazzo and poured terrazzo. Each option offers distinct advantages, and the right choice depends on project scale, schedule, design goals, and long-term performance requirements.

To make an informed decision, it is essential to clearly understand what is terrazzo, how these two systems differ, and where each performs best.

Understanding the Basics of Terrazzo

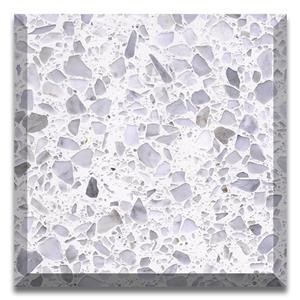

Terrazzo is a composite surface made by combining natural aggregates—such as marble, granite, quartz, or recycled stone—with a cement-based binder. After curing, the surface is ground and polished to achieve a smooth and durable finish. This process creates a long-lasting material known for strength, visual depth, and minimal maintenance.

Both precast and poured systems rely on the same fundamental principles. The key difference lies in where and how the terrazzo surface is produced.

What Is Poured Terrazzo?

Poured terrazzo is created directly on the construction site. Installers prepare the substrate, install divider strips, pour the terrazzo mixture in place, allow it to cure, and then grind and polish the surface on-site. This method allows for seamless, continuous surfaces and custom patterns that flow across large areas.

Poured terrazzo works well for projects that demand complex layouts or artistic designs integrated directly into the floor. However, the on-site process requires skilled labor, controlled environmental conditions, and sufficient time for curing and finishing.

What Is Precast Terrazzo?

Precast terrazzo is manufactured in a factory environment under controlled conditions. Producers cast slabs, stair treads, wall panels, and custom components off-site, then transport them to the project location for installation. This approach ensures consistent color, density, and surface quality across all elements.

Precast terrazzo is commonly used when schedules are tight or when the project requires precise dimensions and repeatable results. It is especially effective for large buildings that need reliable performance and visual consistency.

Key Differences Between Precast and Poured Terrazzo

1. Installation Speed and Project Control

Poured terrazzo depends heavily on site conditions, weather, and labor availability. Delays can occur if curing times extend or surface finishing takes longer than expected.

Precast systems reduce these uncertainties. Since components arrive finished, installation becomes faster and more predictable. This advantage makes precast terrazzo a strong solution for large-scale developments with strict timelines.

2. Quality Consistency

Factory production allows precast terrazzo to maintain uniform aggregate distribution and finish quality. This consistency is difficult to achieve with poured systems across very large floor areas.

For projects requiring a visually consistent terrazzo floor throughout multiple levels or zones, precast solutions offer greater control.

3. Design Flexibility

Poured terrazzo allows for fully seamless surfaces and intricate custom patterns. Designers often choose it for statement floors or artistic layouts.

Precast terrazzo, on the other hand, offers flexibility through modular components, custom panel sizes, and detailed fabrication. Precast terrazzo tiles can be used to create clean, structured designs while still offering visual richness.

4. Structural Performance and Durability

Both systems are durable, but precast terrazzo benefits from controlled curing and compression, resulting in dense, stable components. This makes it ideal for high-traffic environments such as airports, schools, and commercial buildings.

Poured terrazzo also performs well but requires proper substrate preparation and expert installation to avoid cracking or surface quality differences.

Maintenance and Long-Term Performance

Terrazzo is known for its low maintenance requirements. Daily cleaning typically involves sweeping and damp mopping with neutral cleaners. Periodic polishing restores surface gloss and extends service life.

Precast terrazzo often requires less corrective maintenance over time due to its controlled production process. Poured terrazzo can perform equally well when installed correctly, but maintenance quality depends more on initial workmanship.

Cost Considerations

Initial installation costs vary depending on project size, labor availability, and design complexity. Poured terrazzo may appear less expensive for smaller custom installations, while precast systems often provide better cost efficiency for large projects due to faster installation and reduced on-site labor.

When evaluating costs, long-term durability and minimal replacement needs make terrazzo one of the most economical surface materials over its lifespan.

Choosing the Right Supply Partner

Regardless of the system chosen, material quality plays a crucial role in project success. Working with a reliable terrazzo and marble supply partner ensures consistent aggregates, stable binders, and proper technical support. Experienced suppliers help align material performance with design requirements, especially for international or large-volume projects.

Which System Is Right for Your Project?

Precast terrazzo is ideal for projects that prioritize speed, consistency, and large-scale repetition. It works especially well for commercial buildings, transportation hubs, educational facilities, and multi-story developments.

Poured terrazzo remains a strong choice for projects focused on artistic expression, seamless surfaces, and fully custom layouts. It suits boutique spaces, cultural buildings, and unique design statements.

Final Thoughts

Both precast and poured terrazzo offer exceptional durability, timeless appearance, and long-term value. The choice between them should be based on project scale, design intent, construction schedule, and quality control needs.

By understanding the strengths of each system and working with experienced professionals, designers and developers can select the terrazzo solution that best supports both performance and aesthetics—ensuring a surface that remains functional and beautiful for decades.