How Precast Terrazzo Slabs Are Manufactured

A Complete Guide from Raw Materials to Finished Terrazzo Floors

Precast terrazzo slabs have become a preferred choice for commercial and architectural projects worldwide due to their durability, consistency, and design flexibility. As a professional terrazzo and marble supply manufacturer, Dongxing Group specializes in producing high-quality inorganic precast terrazzo slabs for global markets.

In this article, we explain what is terrazzo, what terrazzo is made of, and provide a step-by-step overview of how terrazzo slabs are manufactured in a modern factory environment. This guide is intended for architects, contractors, and project owners seeking reliable terrazzo floor solutions.

What Is Terrazzo?

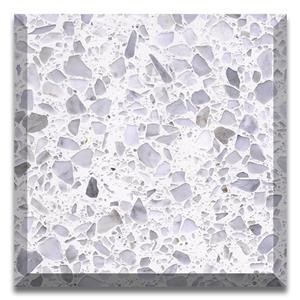

Terrazzo is a composite flooring material made by embedding stone aggregates into a cement or resin binder, then grinding and polishing the surface to achieve a smooth, decorative finish. Traditionally developed in Italy, terrazzo floors are now widely used in airports, shopping malls, restaurants, hotels, and residential interiors.

Today, terrazzo is mainly divided into two categories:

Inorganic (cement-based) terrazzo

Epoxy (resin-based) terrazzo

At Dongxing Group, we focus on inorganic precast terrazzo, which is especially suitable for large-scale commercial applications due to its strength, fire resistance, and long service life.

What Is Terrazzo Made Of?

Understanding what terrazzo is made of is essential to evaluating its performance. Precast terrazzo slabs typically consist of:

Natural stone aggregates (marble chips, granite chips, quartz)

Mineral pigments for color consistency

Water and additives to enhance strength and workability

All aggregates used in Dongxing Group’s terrazzo slabs are carefully selected from high-quality stone blocks, ensuring stable color, controlled particle size, and long-term durability.

Step 1: Raw Material Selection and Preparation

The manufacturing process begins with the selection of raw materials. Stone blocks are processed into aggregates of different sizes, usually ranging from 3 mm to 12 mm, depending on design requirements.

This stage is critical for achieving consistent terrazzo slabs. Uniform aggregates ensure even distribution, visual balance, and structural integrity in the final terrazzo floor.

Step 2: Mold Preparation and Design Planning

Before casting, steel or reinforced molds are prepared according to the required terrazzo slab size and thickness. Common slab dimensions include:

(600 × 600 mm,800 × 800 mm,2400 ×1600 mm,3200×1600mm)

Custom sizes for specific projects

Design layouts, including aggregate ratio and color distribution, are confirmed at this stage. This allows Dongxing Group to offer customized terrazzo slab solutions for various architectural styles.

Step 3: Mixing the Terrazzo Composition

Aggregates, cement binders, pigments, and water are precisely measured and mixed using industrial equipment. Accurate batching is essential to maintain consistent color and physical properties across multiple terrazzo slabs.

This controlled mixing process differentiates professional terrazzo and marble supply manufacturers from small-scale producers.

Step 4: Casting and Vibration Compaction

The mixed terrazzo material is poured into molds and compacted using vibration technology. This step removes air pockets, increases density, and improves the mechanical strength of the terrazzo slab.

Proper compaction is especially important for terrazzo floor applications in high-traffic areas such as restaurants, shopping centers, and transportation hubs.

Step 5: Curing and Strength Development

After casting, terrazzo slabs undergo a controlled curing process. Inorganic terrazzo requires sufficient curing time to achieve optimal hardness and stability.

At Dongxing Group, curing conditions are carefully managed to prevent cracking, shrinkage, or color variation, ensuring long-lasting terrazzo floors.

Step 6: Surface Grinding and Polishing

Once cured, the slabs are ground in multiple stages using industrial polishing machines. This process exposes the stone aggregates and creates the characteristic terrazzo appearance.

Polishing levels can be adjusted according to project needs, from matte finishes to high-gloss surfaces suitable for luxury interiors.

Step 7: Quality Inspection and Packaging

Each terrazzo slab undergoes strict quality control checks, including:

Surface flatness

Color consistency

Dimensional accuracy

Structural integrity

Approved slabs are then carefully packaged for export, ensuring safe delivery to international markets.

Why Choose Precast Terrazzo Slabs?

Compared to poured-in-place terrazzo, precast terrazzo slabs offer several advantages:

Faster installation

Factory-controlled quality

Consistent appearance

Reduced on-site labor

Ideal for large commercial terrazzo floor projects

These benefits make precast terrazzo an efficient solution for modern construction.

Dongxing Group: Professional Terrazzo and

Marble Supply

With decades of experience in stone manufacturing, Dongxing Group provides reliable terrazzo and marble supply solutions for global clients. Our inorganic precast terrazzo slabs are widely used in restaurants, retail spaces, hotels, and public buildings.

From raw material selection to finished terrazzo slabs, every step is handled with precision and professionalism to meet international standards.

Conclusion

Understanding how precast terrazzo slabs are manufactured helps architects and contractors make informed material decisions. From aggregates and cement to polishing and inspection, each stage contributes to the performance and aesthetics of the final terrazzo floor.

As demand for durable and sustainable materials grows, precast terrazzo continues to be a timeless and practical choice for modern architecture.