Precast Terrazzo vs Poured Terrazzo for Large Projects

Terrazzo has been used as a flooring and surface material for centuries, yet it continues to evolve alongside modern architecture and interior design. Today, terrazzo is widely specified in airports, shopping centers, offices, museums, hotels, and large residential developments. While traditional poured terrazzo is still known in the industry, many contemporary projects now rely on precast terrazzo slabs and tiles produced in factory environments.

Understanding the differences between precast terrazzo and poured terrazzo helps architects, designers, and developers make better material decisions. This guide explains what terrazzo is, how modern terrazzo flooring is produced, and why factory-made terrazzo has become the preferred solution for large and complex projects.

What Is Terrazzo?

Terrazzo is a composite material made by combining mineral aggregates—most commonly marble chips— with inorganic binders. After curing, the surface is ground and polished to achieve a smooth and dense finish. The result is a hard-wearing surface that balances decorative appearance with long-term performance.

In modern construction, terrazzo is no longer limited to traditional methods. Today’s terrazzo flooring is often manufactured in factories as slabs or tiles, allowing for controlled production, stable quality, and predictable results across large quantities.

Understanding Poured Terrazzo

Poured terrazzo is produced directly on the job site. Aggregates and binders are mixed, placed, cured, and polished in multiple stages. This process requires skilled labor, extended curing time, and favorable site conditions.

While poured terrazzo can create seamless surfaces, it also introduces challenges. Variations in temperature, humidity, and workmanship can affect surface quality. Large areas often require longer schedules and more on-site coordination, which can increase risk for complex commercial projects.

Because of these factors, poured terrazzo is now less common in large international developments where timelines and consistency are critical.

What Is Precast Terrazzo?

Precast terrazzo refers to terrazzo slabs, tiles, steps, and panels that are manufactured in controlled factory conditions. Instead of mixing and finishing on site, each terrazzo element is produced, cured, and polished before delivery.

This approach allows manufacturers to maintain stable color, even aggregate distribution, and consistent thickness. Precast terrazzo slabs arrive on site ready for installation, reducing labor demands and minimizing uncertainty during construction.

At Dongxing Group, precast terrazzo is produced using standardized processes designed for architectural applications. From raw material selection to final polishing, each step is carefully managed to ensure reliable quality across large-scale orders.

Key Differences Between Precast and Poured Terrazzo

Production Environment

Poured terrazzo depends heavily on site conditions, while precast terrazzo is produced indoors under controlled settings. This difference directly affects quality stability.

Installation Time

Precast terrazzo slabs can be installed using standard stone installation methods. This shortens construction schedules compared to poured systems that require multiple curing and polishing stages.

Surface Consistency

Factory production ensures even aggregate placement and surface finish across all slabs. This level of consistency is difficult to achieve with on-site methods.

Project Planning

Precast terrazzo supports better planning for logistics, quantity control, and long production runs, especially for international projects.

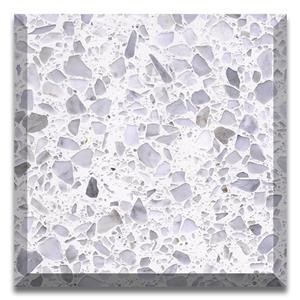

<Precast terrzzo>

<Precast terrzzo>

Why Precast Terrazzo Flooring Is Widely Used

Durability for High-Traffic Areas

Precast terrazzo flooring performs well in areas with heavy foot traffic. Its dense structure resists wear, making it suitable for public buildings and commercial interiors.

Design Control

By producing terrazzo in slabs or tiles, designers can define colors, aggregate size, and finishes early in the design stage. This improves coordination between design intent and final results.

Lower Long-Term Maintenance

Once installed, terrazzo flooring requires routine cleaning and occasional surface care. Its long service life reduces replacement frequency compared to many other flooring materials.

Terrazzo Tiles and Slabs in Modern Architecture

Terrazzo tiles and large-format slabs are increasingly used beyond flooring. They appear in wall cladding, staircases, countertops, and interior feature surfaces. This flexibility allows architects to create unified material language across different areas of a project.

Precast terrazzo also works well alongside natural stone. Many terrazzo and marble supply companies offer coordinated solutions that help designers balance natural textures with engineered consistency.

Installation Considerations for Precast Terrazzo

Proper installation is essential to achieve the best performance from terrazzo flooring. Substrate preparation, adhesive selection, and joint treatment should follow professional stone installation standards.

Because precast terrazzo arrives with a finished surface, on-site work focuses mainly on placement and alignment. This reduces noise, dust, and disruption during construction, which is especially important in occupied or phased projects.

Choosing the Right Terrazzo Supplier

Material quality alone is not enough. Successful terrazzo projects depend on experienced suppliers who understand production, packaging, and international delivery requirements.

As a global terrazzo and marble supply provider, Dongxing Group supports projects with stable production capacity and technical coordination. This helps ensure that terrazzo slabs meet design expectations while aligning with construction schedules.

Is Precast Terrazzo the Right Choice for Your Project?

For projects that prioritize durability, visual consistency, and predictable installation, precast terrazzo offers clear advantages. It combines the classic appeal of terrazzo with modern manufacturing efficiency.

By understanding the differences between precast and poured terrazzo, project teams can select materials that support both design goals and long-term performance.