Terrazzo Tiles: Specification Guide for Architects

Terrazzo has become a widely specified surface material in contemporary architecture, valued for its durability,

visual depth, and long service life. From transportation hubs to educational buildings and commercial interiors,

terrazzo floors are often selected for projects that require both performance and design consistency.

For architects, specifying terrazzo involves more than selecting colors or aggregate sizes. Understanding terrazzo material composition, production methods, dimensional tolerances, and installation requirements is essential to achieving predictable results on site. This practical guide outlines the key specifications architects should consider when working with modern terrazzo systems, with a focus on factory-produced terrazzo products used in architectural projects today.

What Is Terrazzo?

Terrazzo is a composite surface material made by embedding stone aggregates into a binding matrix, followed by grinding and polishing to achieve a smooth finish. Historically, terrazzo was produced using cement-based binders and installed directly on site. Today, terrazzo is also widely manufactured as precast slabs and tiles under controlled factory conditions.

In architectural specifications, terrazzo is recognized for its high compressive strength, abrasion resistance, and ability to maintain appearance over long periods of use. These qualities make it suitable for both public and private spaces where surface performance is a priority.

Terrazzo Material Composition

At its core, terrazzo material consists of three main components: aggregates, binders, and surface treatment.

Aggregates typically include marble chips, but may also involve granite, quartz, or other mineral materials depending on design intent. Aggregate size and distribution play a major role in the visual character of the finished surface.

In inorganic terrazzo systems, mineral-based binders are used instead of synthetic resins. This results in a dense, stable structure with strong resistance to heat, aging, and long-term wear. Surface finishing through grinding and polishing reveals the aggregate and creates the final appearance specified by the design team.

How Are Terrazzo Floors Made?

Understanding how are terrazzo floors made helps architects evaluate performance expectations and construction timelines.

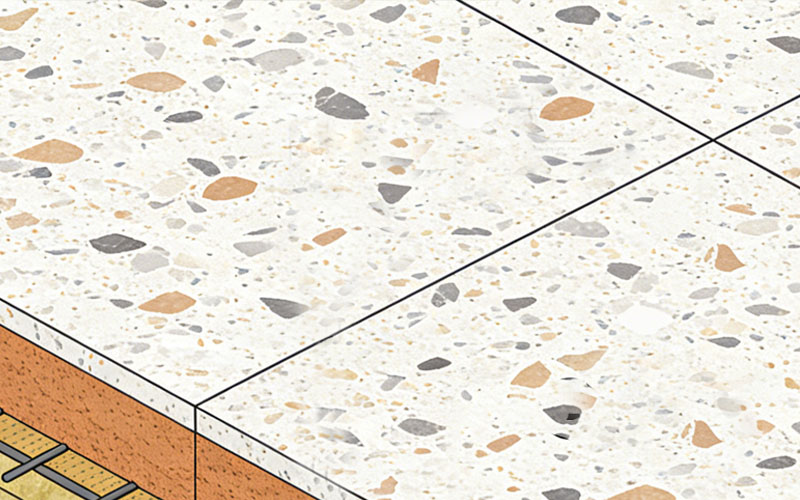

In modern practice, many terrazzo floors are produced as precast elements. Slabs or tiles are manufactured in factories where raw materials are measured, mixed, molded, cured, and polished under consistent conditions. This controlled process allows manufacturers to manage color accuracy, thickness tolerance, and surface quality before the material reaches the job site.

Compared to traditional site-based methods, factory production reduces environmental variables and improves predictability for large-scale architectural projects.

Terrazzo Tiles in Architectural Design

Terrazzo is commonly supplied in slab or tile form, allowing flexibility in layout and application. While large-format slabs are often used for expansive floor areas, terrazzo tiles offer modular control and are well suited for projects with phased installation schedules.

Architects may encounter specifications that reference terazzo tiles in project documentation, particularly in international or legacy specifications. Regardless of terminology, factory-produced terrazzo tiles provide consistent appearance and simplify coordination with other interior finishes.

Performance Requirements for Terrazzo Floors

When specifying terrazzo floors, architects should consider performance criteria such as wear resistance, slip resistance, and structural compatibility with the substrate.

Terrazzo performs well in high-traffic environments due to its dense surface and resistance to abrasion. Proper surface finishing can also address slip resistance requirements without compromising visual clarity. Thickness, reinforcement options, and backing systems should be evaluated based on project conditions and expected load.

Installation Considerations

Precast terrazzo products are typically installed using methods similar to natural stone flooring. Substrate preparation, adhesive selection, joint detailing, and expansion allowances should follow established industry standards.

Because terrazzo arrives on site with a finished surface, installation focuses on placement accuracy rather than surface creation. This reduces on-site dust, noise, and finishing time, which can be beneficial for occupied or fast-track projects.

Coordination with Terrazzo and Marble Supply

Successful terrazzo projects rely on early coordination with experienced terrazzo and marble supply partners. Material samples, mock-ups, and production schedules should be reviewed during the design development phase to ensure alignment with architectural intent.

Manufacturers with experience in large-scale production can support architects by providing technical data, dimensional guidance, and finish options that integrate seamlessly with broader stone and surface specifications.

Design Flexibility and Visual Control

One of terrazzo’s strengths is its ability to support a wide range of design expressions. Aggregate selection, color balance, and surface finish can be adjusted to complement different architectural styles, from minimalist interiors to expressive public spaces.

Factory production enhances visual control by ensuring that terrazzo elements maintain consistent appearance across different batches and installation phases. This is particularly important for projects with large floor areas or long construction timelines.

Conclusion

Terrazzo remains a relevant and reliable material in modern architecture, combining long-term performance with refined visual qualities. By understanding what is terrazzo, how terrazzo floors are made, and how terrazzo material is specified and installed, architects can make informed decisions that support both design intent and construction efficiency.

With proper specification and coordination, terrazzo continues to serve as a practical and enduring surface solution for contemporary architectural projects.