What Is Quartz Made Of? A Professional Guide to Quartz Countertops

What Is Quartz Made Of? Quartz Countertops Explained

Introduction: Why Material Composition Matters

When specifying surface materials for kitchens, bathrooms, or commercial interiors, understanding what a material is made of is as important as how it looks. Quartz has become one of the most widely specified countertop materials worldwide, yet many professionals still ask a fundamental question: what is quartz made of, and how does its composition influence performance, consistency, and long-term use?

Unlike natural stone slabs that vary from quarry to quarry, quartz countertops are engineered surfaces. Their controlled composition allows designers, contractors, and buyers to predict results with far greater accuracy—particularly in large-scale or repeat installations.

This article provides a clear, professional explanation of what quartz is made of, how quartz slabs are produced, and how engineered quartz compares with alternative materials such as quartzite.

What Is Quartz Made Of?

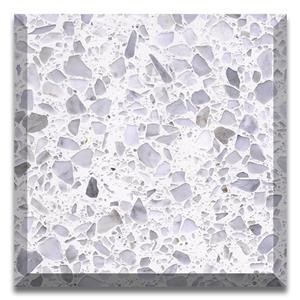

Quartz countertops are manufactured from a blend of ground natural quartz minerals, polymer resins, and color pigments. By weight, most quartz surfaces contain approximately 90–93% natural quartz, with the remaining percentage composed of binding agents and additives.

Natural quartz is one of the hardest minerals found in the earth. When crushed into fine aggregates and combined with resins, it forms a dense, non-porous slab designed for building materials use. This engineered composition allows manufacturers to control texture, color distribution, and slab thickness with high precision.

From a specification standpoint, this means quartz offers repeatable results, making it suitable for projects where visual and technical consistency are required.

How Quartz Countertop Slabs Are Manufactured

Quartz slab production takes place in factory-controlled environments rather than quarries. The process typically involves mixing quartz aggregates with resin binders, followed by compaction under high pressure and vibration. The slabs are then cured, calibrated, and finished to achieve a smooth, uniform surface.

Because the process is industrial rather than natural materials, manufacturers can regulate:

Slab density

Surface finish

Color uniformity

Dimensional tolerance

This level of control explains why quartz countertop slabs are commonly used in hotels, residential developments, and commercial spaces where consistency across multiple units is critical.

Quartz Countertops vs Natural Stone Surfaces

One of the most common comparisons in material selection is quartz vs quartzite. While both materials share a similar name, their composition and performance differ significantly.

Quartzite is a natural stone formed through natural materials processes. Each slab is unique in veining, color variation, and internal structure. Quartz, by contrast, is engineered to deliver uniform appearance and predictable behavior.

For professionals, the distinction matters. Quartz offers:

Consistent color across batches

Stable performance in controlled indoor environments

Simplified maintenance requirements

Quartzite, while visually striking, may present variability that complicates installation and long-term upkeep.

Performance Characteristics of Quartz Countertops

Because quartz slabs are non-porous, they resist moisture absorption under normal use conditions. This characteristic reduces the risk of staining and supports hygienic surface performance, especially in kitchens and food preparation areas.

Quartz countertops also demonstrate strong resistance to everyday wear, making them suitable for high-use residential and light commercial applications. However, like all engineered materials, quartz performs best when used within its intended parameters—particularly avoiding excessive heat exposure or outdoor installation.

For white quartz countertops, controlled pigmentation ensures color clarity while minimizing visual inconsistency across large surfaces.

White Quartz Countertops and Design Applications

White quartz countertops remain one of the most requested finishes due to their clean appearance and adaptability. Because pigments are added during manufacturing, white quartz can achieve a consistent tone that is difficult to guarantee with natural stone.

Designers often specify white quartz for:

Modern residential kitchens

Hospitality interiors

Retail and office spaces

Its neutral base allows it to integrate easily with wood, metal, and other architectural materials without dominating the visual hierarchy of a space.

Quartz Slabs in Supply and Distribution

From a supply perspective, quartz slabs are typically distributed through specialized stone suppliers and quartz countertop slab manufacturers. Unlike quarried materials, availability is less affected by natural materials limitations, allowing for more reliable lead times.

For terrazzo and marble supply companies expanding into engineered surfaces, quartz represents a logical extension due to its stable production cycle and consistent demand.

Long-Term Value and Specification Considerations

When evaluating quartz countertops for a project, professionals should consider not only initial appearance but also lifecycle performance. Quartz surfaces tend to maintain their finish with routine care, reducing long-term maintenance effort compared to more porous materials.

Over time, predictable performance and reduced replacement risk contribute to lower overall project costs—an important factor in both residential developments and commercial installations.

Conclusion: What Quartz Is—and Why It Matters

So, what is quartz made of? At its core, quartz is an engineered material designed to combine the strength of natural quartz with the reliability of modern manufacturing. Its composition allows for consistency, controlled aesthetics, and dependable performance across a wide range of interior applications.

For architects, designers, and buyers seeking a surface that balances appearance with practicality, quartz countertops remain a reliable choice—especially when consistency, maintenance control, and specification accuracy are priorities.